In the field of Plant Maintenance, there are many services available for maintenance support. If you’re unsure which service is best suited for your plant maintenance requirements, our team of experts can provide guidance to help you make the right choice. We offer a range of services for Plant Maintenance, including:

PULLEY REMOVAL SYSTEMS

Safe, Efficient Tooling for the removal and installation of confined space pulleys and equipment. Our SLED Pulley Removal System allows for pulley removal fully outside the conveyor frame and walkways, and allows for side removal from areas with Zero lift height confined spaces.

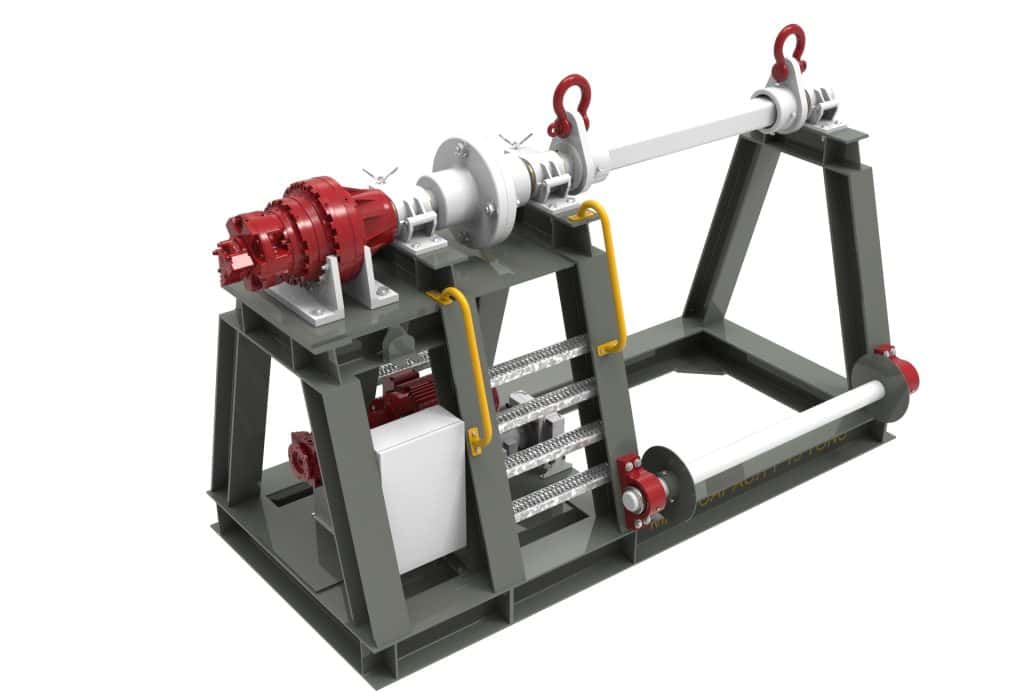

C-HOOK PULLEY REMOVAL SYSTEM

Safe, Efficient Tooling for the removal and installation of confined space pulleys and equipment. Remote controlled lifting point allows for the removal of all pulley weights and sizes up to the capacity of the C-Hook.

BELT WINDERS SYSTEMS

We specialize in Mine Duty Belt Winder Systems. These systems include Belt Winders, Belt Let-Off Stands and Belt Lifting Beams.

CONVEYOR BELT LIFTING SYSTEMS

Safe, Efficient Tooling for the removal and installation of idlers and belt maintenance activities.

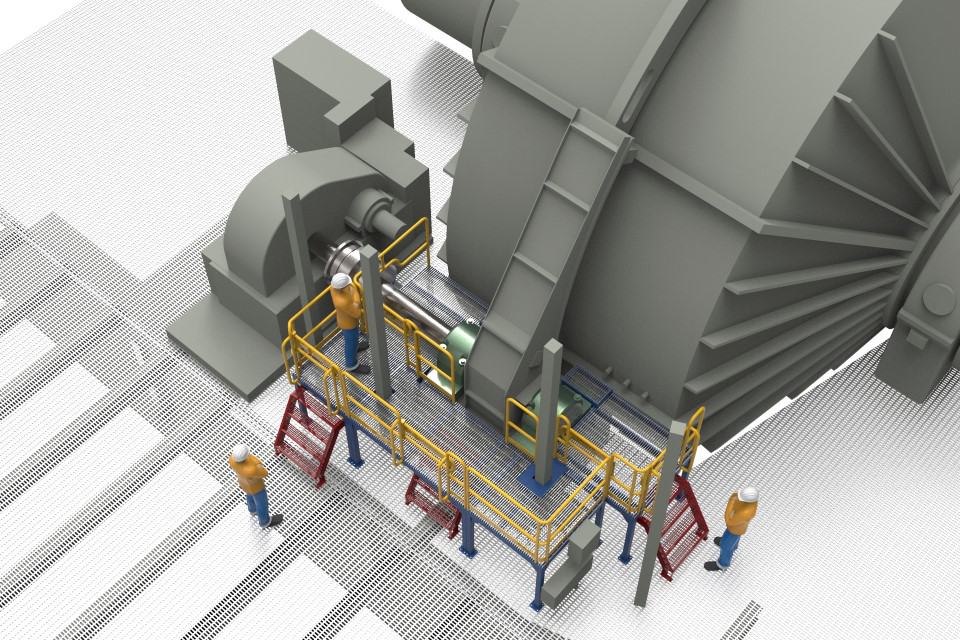

SAFE MAINTENANCE AND ACCESS PLATFORMS

We scan the area where the platform is needed and produce a design that will meet your safety, work area and access needs.

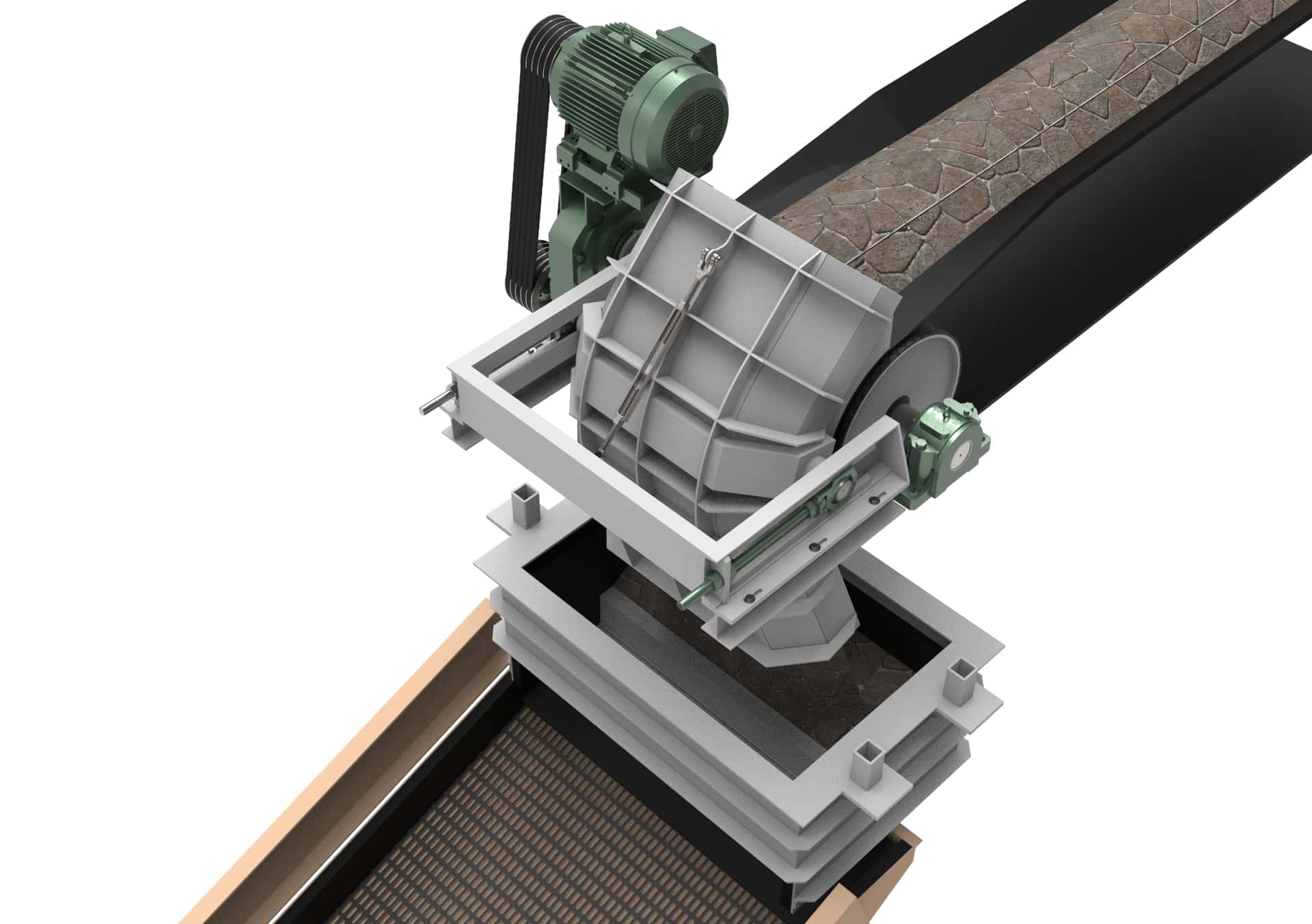

CONVEYOR AND SCREENING FLOW CHUTE DESIGN

Using Discrete Element Modeling, we can verify the effectiveness of a chute design. The Flow Chute design shown here improved the flow from 800 TPH to 1,200 TPH and allowed 100% screen deck utilization by directing the material energy behind the screen so that the material did not impact the screen deck.

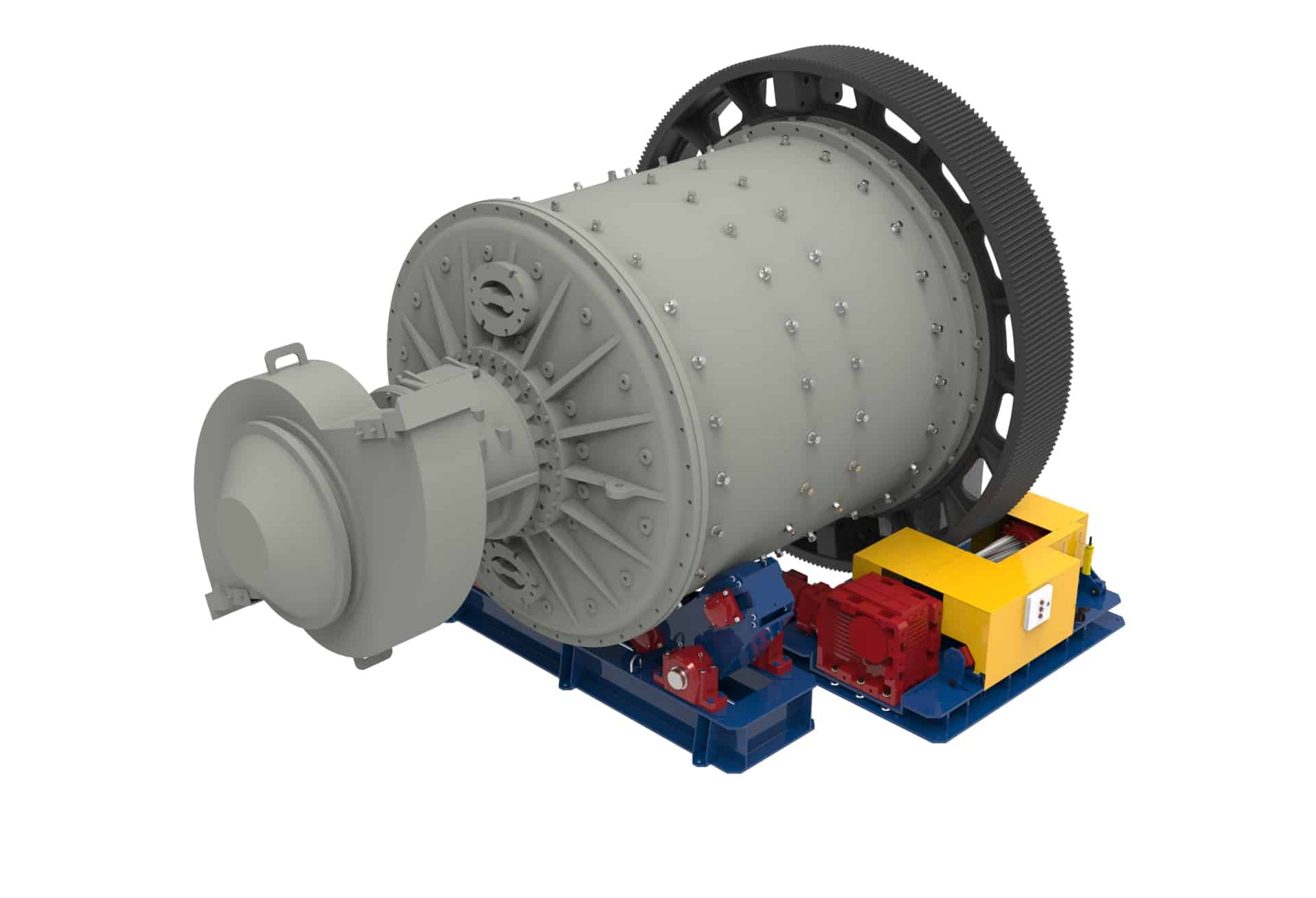

CUSTOM MECHANICAL SYSTEM DESIGN

Our custom mechanical system design services are tailored to meet the unique requirements of your project, no matter how complex or specialized. We have the experience and expertise to deliver solutions that optimize performance, reduce costs, and increase efficiency.

From concept to completion, our team works closely with you to ensure that every aspect of the design process meets your exact specifications. We use the latest design tools and software to create detailed 3D models and simulations, allowing you to visualize and refine your system before it is built.

SELF-LATCHING PULLEY HOOK

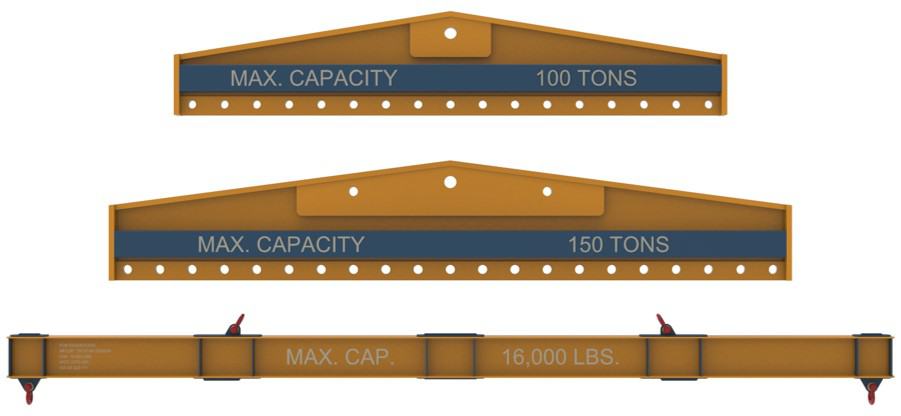

Rigging and Lifting Tooling Design

Refers to the process of designing specialized equipment or tools that are used to lift and move heavy loads. The design process involves analyzing the requirements of the lifting operation, such as the weight and dimensions of the load, and determining the most efficient and safe way to lift and move it. The rigging and lifting tooling design process also takes into account factors such as environmental conditions, safety considerations, and compliance with regulatory requirements. The end result is a specialized tool or set of tools that are optimized for the specific lifting operation, ensuring safety, efficiency, and effectiveness.

3D Part Scanning

At Engineering Support, we use the Trimble X7 3D scanner to provide you with the best 3D part scanning service available. Our expert team utilizes its advanced technology to capture every detail of your parts with high accuracy and precision, reducing rework and saving you time and money. With our efficient workflows and user-friendly software, we ensure that you receive the most accurate and reliable 3D models of your parts. Trust Engineering Support to handle your 3D part scanning needs with confidence.

CONVEYOR BELT CLAMPING

We design Custom Conveyor Belt Clamping systems to make your belt maintenance Safe, Efficient and Easy to lock-out and unlock to get your conveyor up and running quickly. Contact us for your conveyor belt maintenance needs.

PROCESS MIXING STATIONS

Custom, Efficient process mixing stations to meet your specific needs.

FEA ANALYSIS & VERIFICATION

Using the latest 3D scanning technology, we capture precise measurements of your construction project to create an accurate digital model of the as-built conditions. Our experienced team of engineers and technicians then analyze the data to identify any discrepancies between the as-designed and as-built conditions. With our 3D as-built verification service, you’ll benefit from increased accuracy and efficiency, reduced risk of errors and rework, and improved project outcomes.

CUSTOM EQUIPMENT & DESIGN

We offer comprehensive Design Engineering solutions that include 3D scanning, CAD modeling, prototyping, and testing. Our services are perfect for those who need a completely new design, to replicate an existing product, and improve its design or functionality.